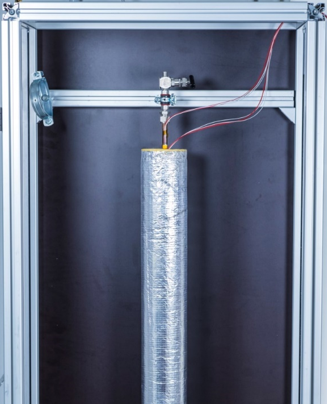

Characterization of cylindrical heat pipes

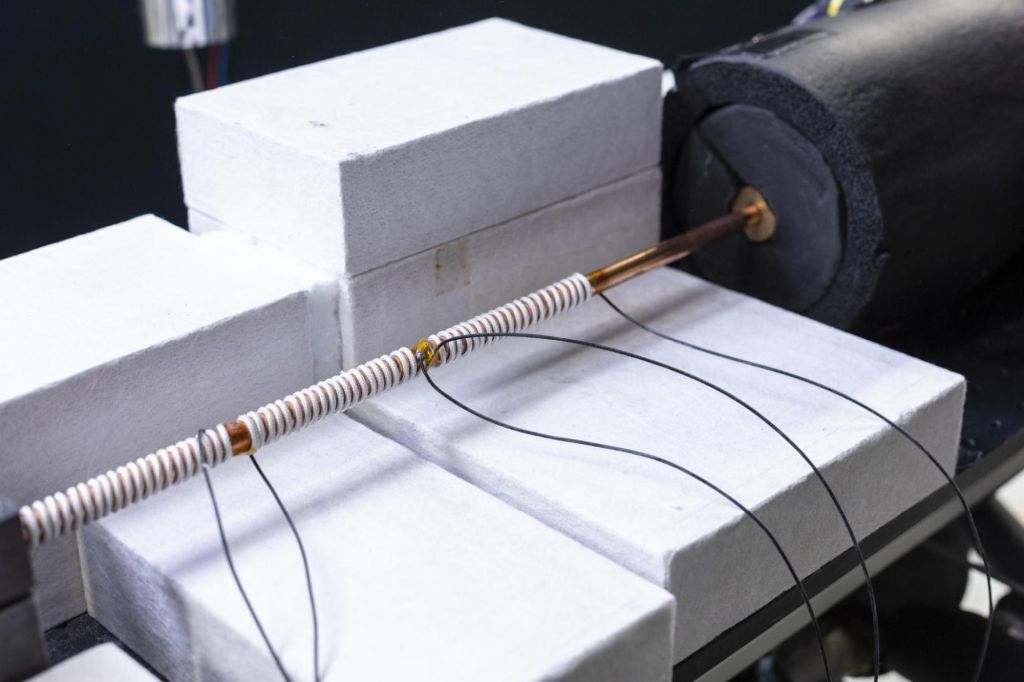

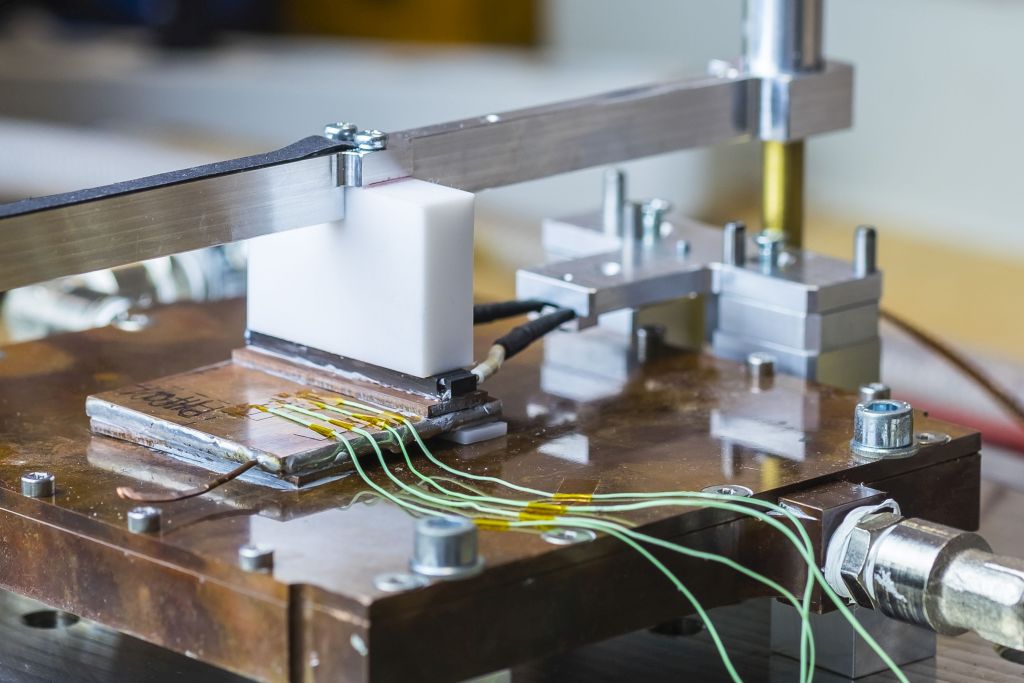

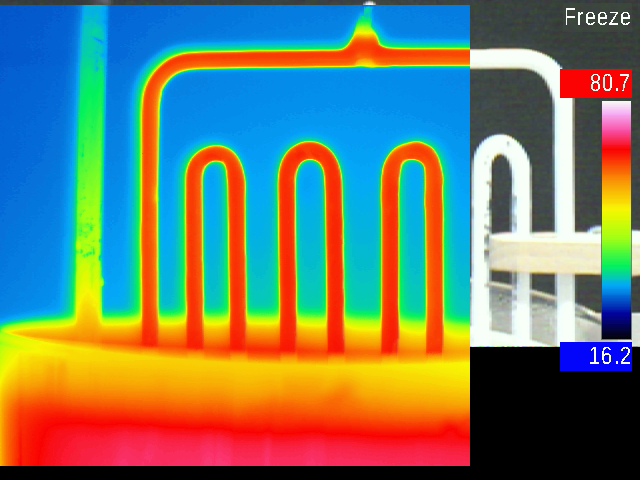

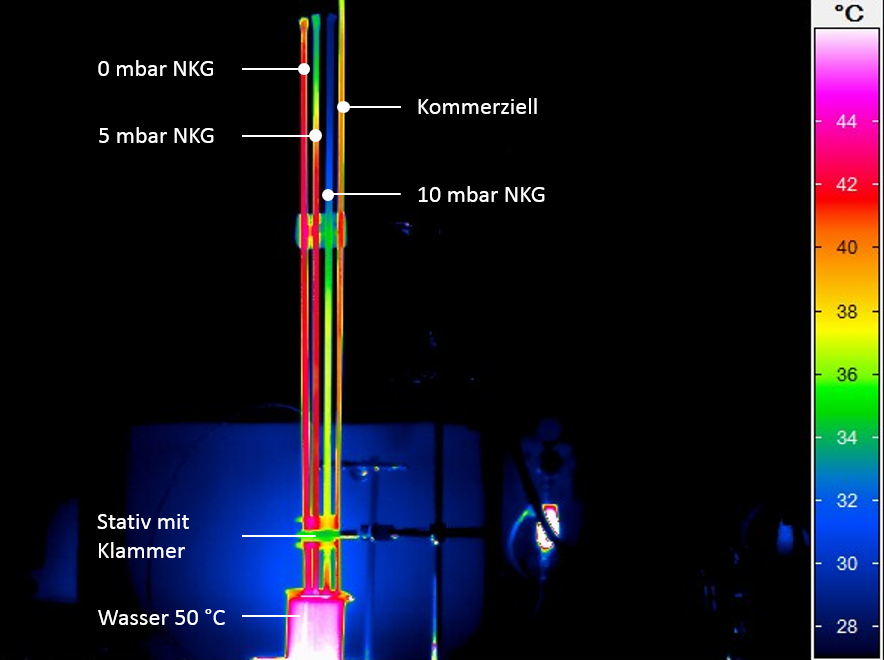

The Competence Center Heat Pipes has developed a test bench for the characterization of cylindrical heat pipes which is characterized, among other things, by its high angle of inclination precision. We can use it to flexibly and precisely measure heat pipes in terms of their function from vertical to horizontal, depending on the respective requirements. At the measuring station, we vary the power applied as well as the temperature of the cooling water and determine the thermal resistance and heat transfer limits depending on different operating conditions.

Specification of the measuring station:

- Size: 200 – 2000 mm length, 8 mm – 12 mm diameter

- Temperature range: 10 – 90 °C in the cooling water, up to 200 °C at the heat pipe

- Power range: 10 – 1000 W

- Orientation: -5 – 90° (negative angles: condenser below evaporator)

- Customized variations

Fraunhofer IPM | Fraunhofer ISE

Fraunhofer IPM | Fraunhofer ISE