Large heat transfer in a small space

PHP developed and built at Fraunhofer IPM dissipate heat extremely efficiently: A PHP developed at the institute made of copper with dimensions of 100 × 50 × 2.5 mm3 , for example, has an effective thermal conductivity up to six times higher than a plate of solid copper of the same size – comparable to diamond.

Further advantages of PHP:

Technical simplicity and reliability: The function of heat transport via the reciprocating fluid is independent of position and purely passive. In other words, PHPs function like an integrated water cooling system. However, no moving parts and no power supply are required. This results in high operational stability and reliability. PHP typically operate in both horizontal and vertical orientation.

Stability and weight: The proportion of cavities is significantly smaller compared to conventional heat pipes or vapor-chamber-based heat spreaders. As a result, PHP achieve significantly higher stability as a heat spreader. This is advantageous, for example, with regard to pressing processes in the production of printed circuit boards. At the same time, the weight is lower than that of a solid plate. This is an important advantage, especially in the aerospace industry.

Extremely good heat spreading effect due to the active principle of the PHP. The effect depends on the position and size of the hot component and the heat sink.

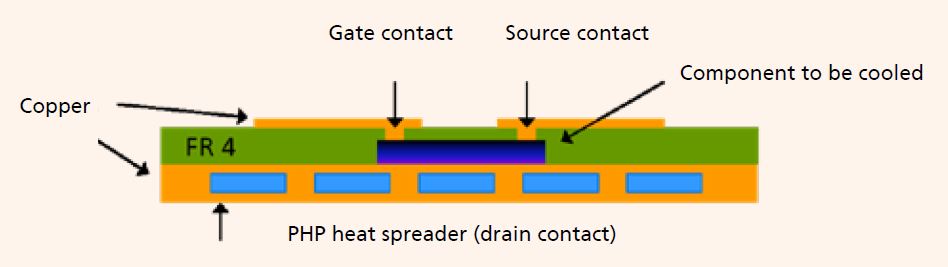

Integrability: With thicknesses of only 2-3 mm, the PHP is flat and very compact. Especially for embedded power components, this enables very good thermal coupling.

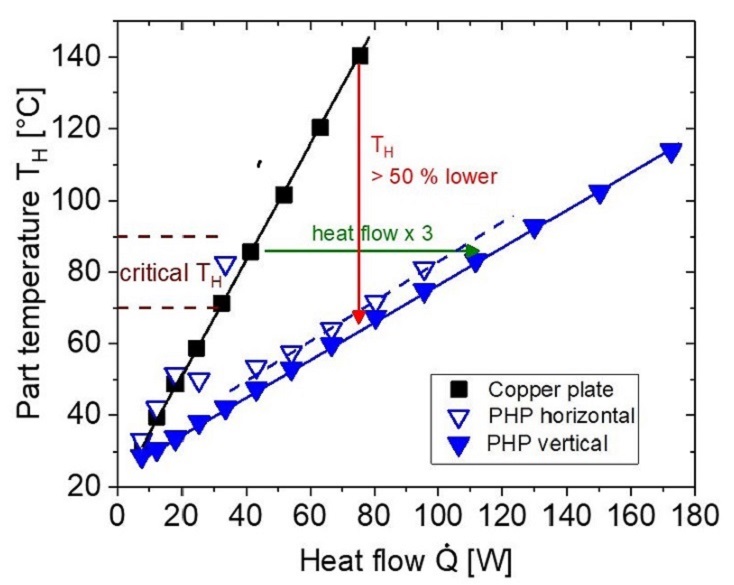

Figure 2 shows performance data for a PHP developed at Fraunhofer IPM made of copper with dimensions of just 100 × 50 × 2.5 mm3. The heater attached to the PHP – it has an area of 8 × 50 mm² – represents a heating electronic component. Electrical components that are deheated with a PHP instead of a copper plate heat up significantly less.

All performance data can be found on the Functionality and Performance Data of Heatpipes page.

Fraunhofer IPM | Fraunhofer ISE

Fraunhofer IPM | Fraunhofer ISE